Remaining offer

OFFER

(automotive, metallurgy, environmental protection, cooperation, R&D projects)

What we offer:

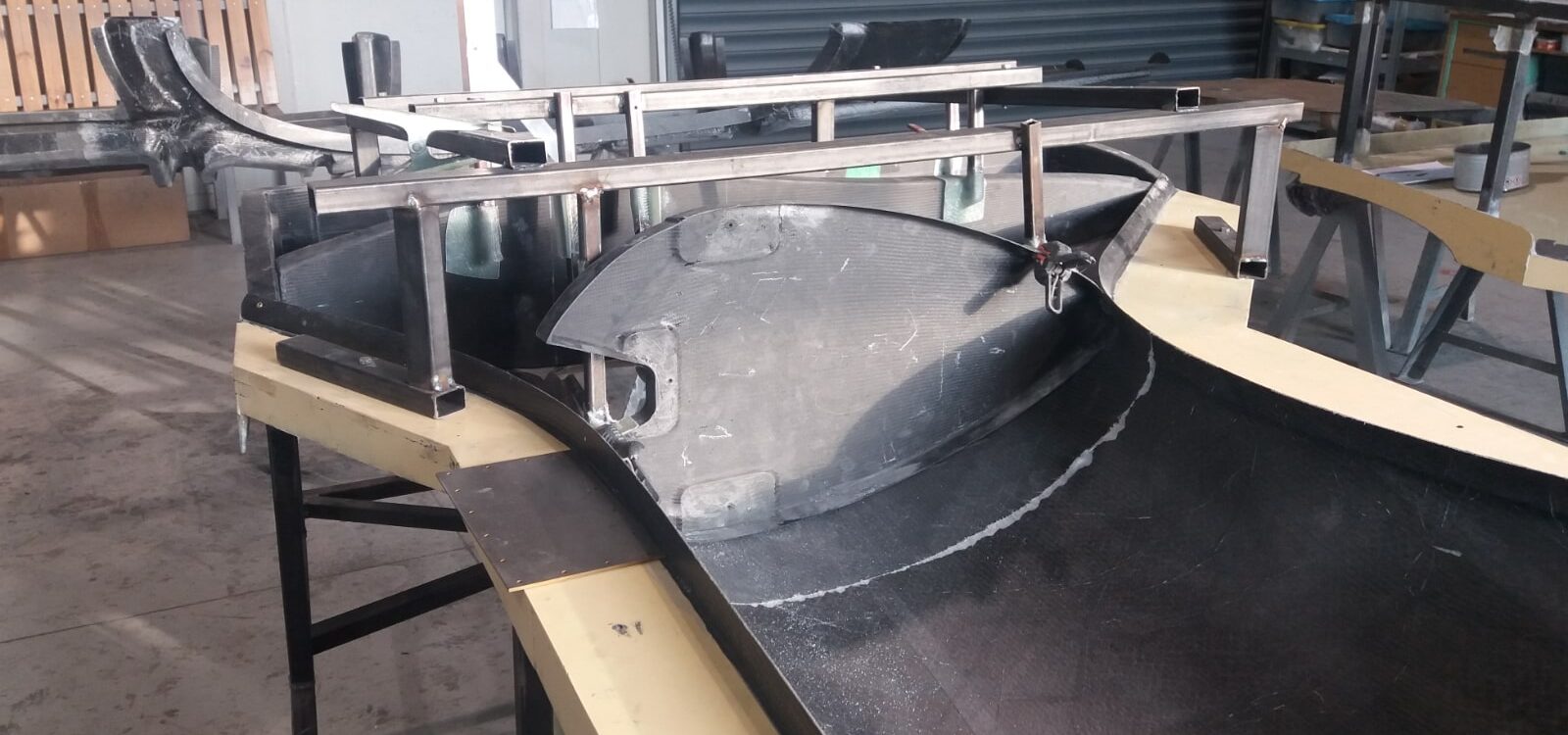

- Production, repair and regeneration of various types and kinds of elements with metal and composite structure. We have experience in design and production of components for assembly and transport/feeder lines, constructed with the use of glass and carbon composites for the automotive industry, metallurgy and defence (e.g. feeder composite leaf springs, repair of assembly line elements for the automotive industry).

- Development and Manufacturing of production moulds and tools (e.g. forms for wind turbine blades, road infrastructure components, industrial fans).

- Design and fabrication of fixtures for static-, and dynamic test and engineering support for test realization.

- Cooperative manufacturing in research and development projects.

- Locksmith-welding services.

- Heat-curing services for composite structures, lacquered elements (max temperature/ element overall dimensions L x W x H [m]: up to 90°C /12.50 x 2.60 x 2.20 and up to 140 °C / 4.00 x 2.60 x 2.20).

- Engineering support for design- and computational analysis work.

Realizations:

1.

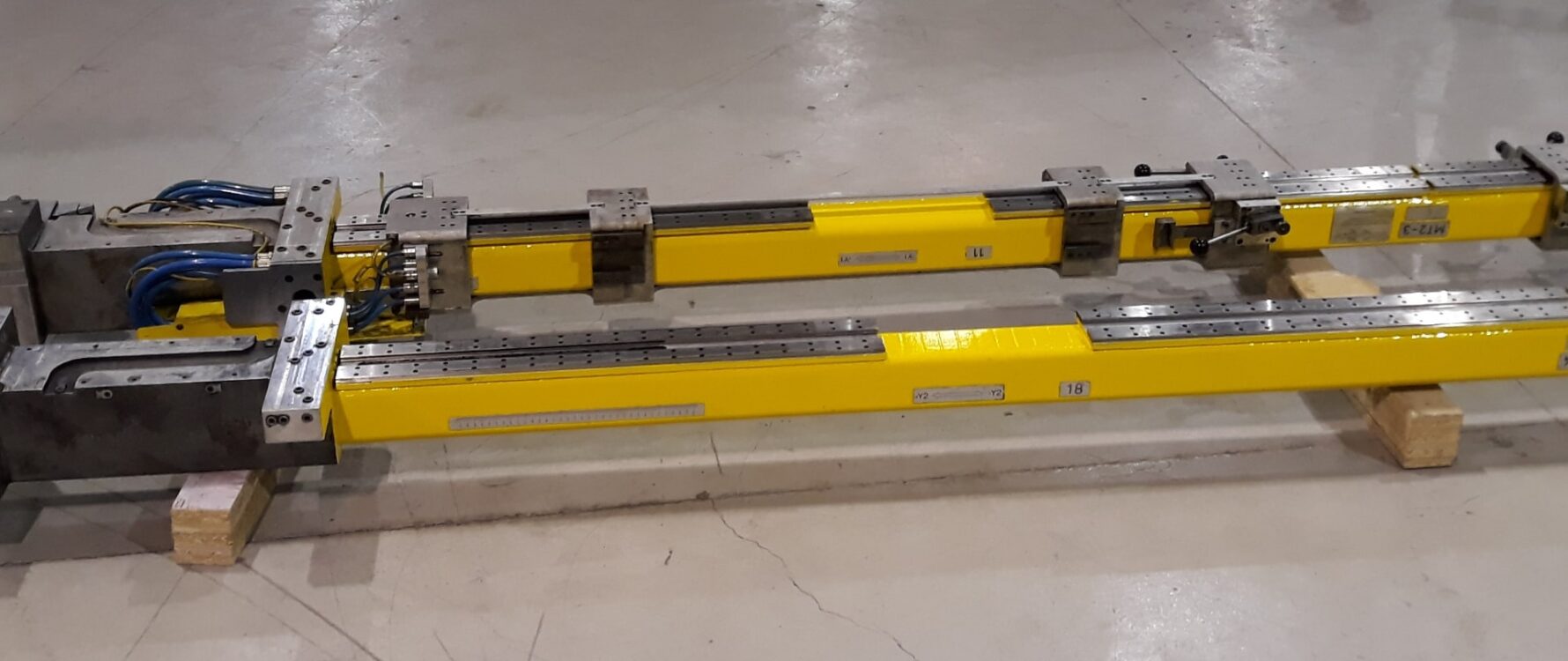

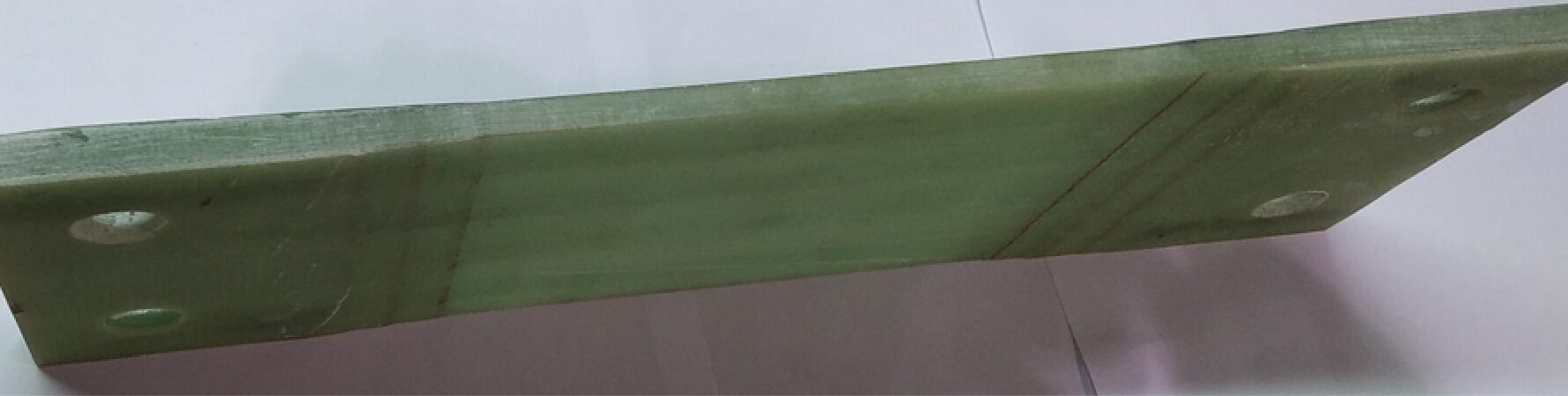

Repair and regeneration of machine parts and devices used in assembly line and metal foundary for automotive industry.

This type of repair (using composite structures) has been already completed for Opel Manufacturing Poland Sp. z o. o., Gliwice and TEKSID Iron Poland, Skoczów.

2.

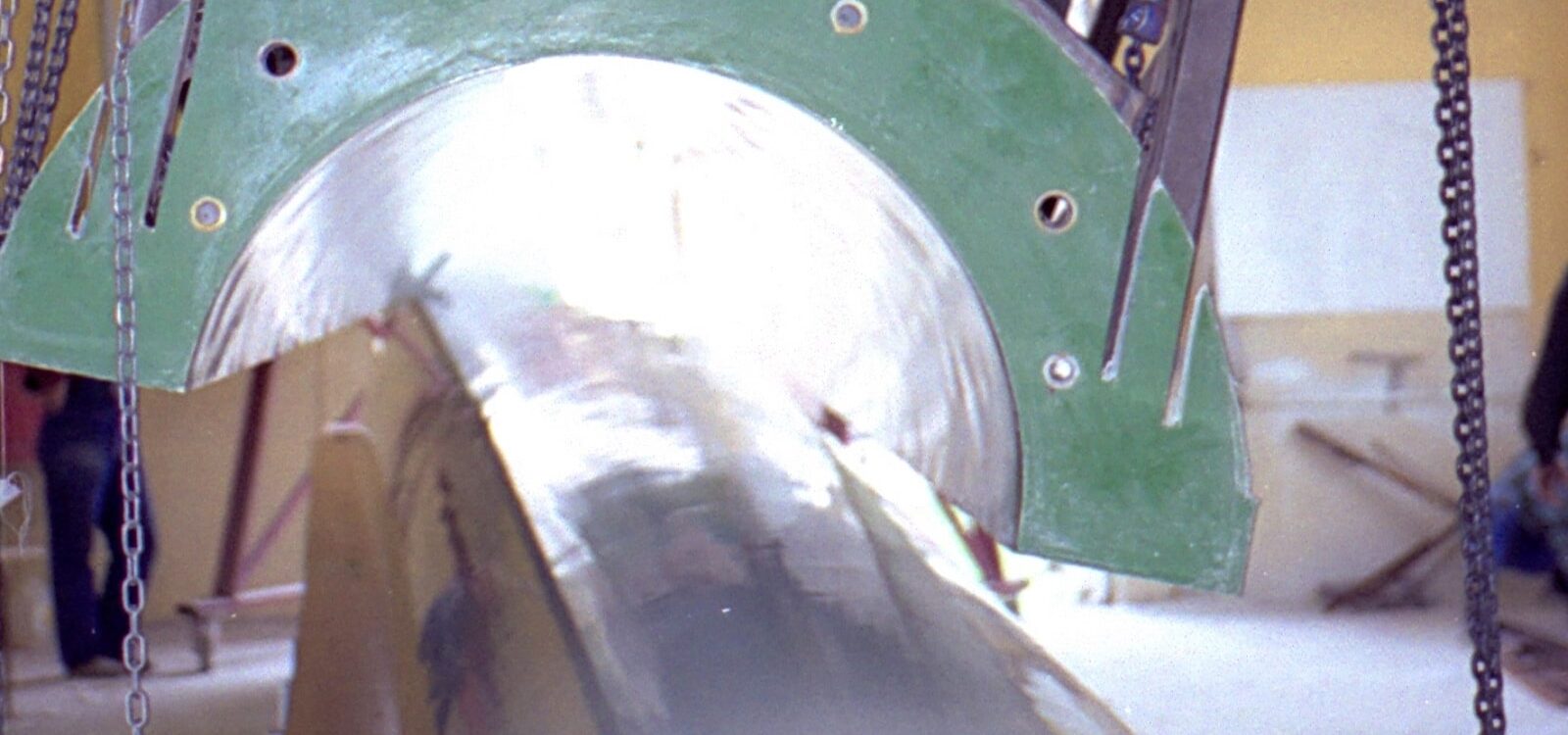

Fabrication of tooling, molds and ready-made blades for a wind turbine based on the Magnus effect.

3.

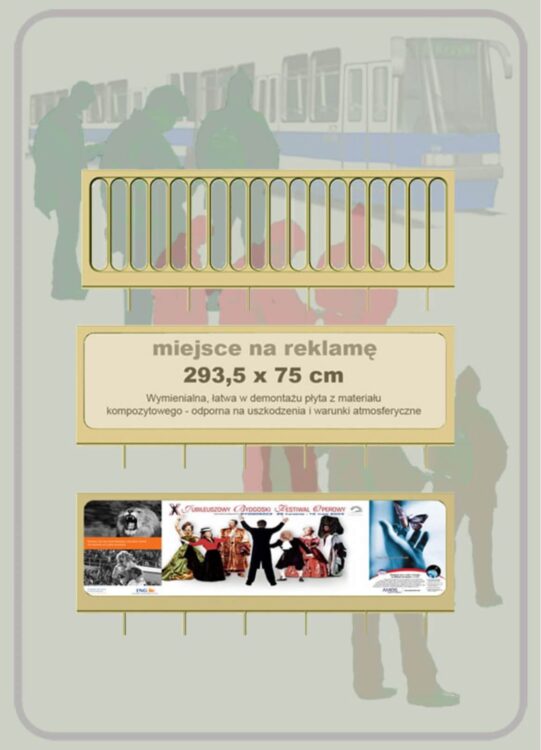

Concept-, and development of composite railings and bridges.

4.

Conceptual-, technical design, and construction of benches and instrumentation, as well as implementation and engineering support in static and dynamic testing.

5.

Manufacturing of moulds for wind turbine blade assemblies – e.g. cooperation with ENERCON GmbH